Waste-to-Energy (WTE) Incineration Solution

At Green Nova Energy, we take pride in employing cutting-edge technology that exceeds international standards.

Our incineration treatment process, equipped with advanced grate furnaces, ensures that flue gas emissions meet and even surpass the EU 2000 standard. Our flue gas emissions also meet the standards of GB18485-2014.

We have also invested in auxiliary facilities such as sewage treatment and fly ash solidification to enhance our environmental performance.

WASTE INCINERATION POWER GENERATION

GREEN NOVA

ENERGY

Solid Waste Management

Our WTE systems manage 157,000+ tonnes of household waste daily and process food, sludge, and hazardous materials efficiently.

• WTE Incineration (MSW, RDF, industrial waste)

• Food and kitchen waste: 8,500+ tonnes/day

• Hazardous waste: 2.4M+ tonnes/year

• Heat supply and waste transport

• Eco-industrial park development

Water Services

With a strong commitment to sustainability, we help cities and industries ensure safe, efficient, and eco-friendly water management.

Our capabilities include:

• Municipal & industrial wastewater treatment: 6.2 million m³/day

• Reusable water supply: 300,000 m³/day

• Clean water distribution: 850,000 m³/day

• River-basin restoration & raw water protection

• Advanced technologies for high-efficiency purification

Clean Energy

Our advanced energy infrastructure is built for resilience, scalability, and sustainability of a carbon-neutral future—powering greener communities for generations to come.

Our clean energy portfolio includes:

• Biomass utilization: Over 8.1 million tonnes/year

• Solar power and wind energy projects

• Environmental remediation for contaminated sites

• Installed capacity: Over 170 MW

OUR COMMITMENT TO INNOVATION & ENVIRONMENTAL EXCELLENCE

Dream it

•

Build it

•

Grow it

•

Dream it • Build it • Grow it •

Innovation-Driven Environmental Technology

We lead with technology that transforms waste, water, and energy systems for a more sustainable future. With over 1,800 granted patents, we are redefining environmental engineering through continuous R&D and advanced industrial applications.

Our key innovation areas include:

• High-value Waste Utilization

• Agricultural and Forestry Biomass Conversion

• Harmless Treatment of Industrial Solid Waste

• Advanced Wastewater Purification

• Intelligent Control Systems Powered by Big Data

From incineration grates to plasma melting systems, our proprietary technologies have broken global monopolies—positioning us as a world-class solution provider in the environmental sector.

Business Scope

Incineration Process

waste-to-energy (WTE) incineration plant

The schematic diagram shows the process of converting municipal solid waste into energy through combustion, while also illustrating the flue gas cleaning systems involved to meet environmental standards.

• Incineration/Combustion: the most efficient and non-harmful way to process large scale of waste

• Waste will be reduced by 80% in weight and 90% in volume

Incineration Grate: EB Grate l / EB Grate ll / EB Grate III

Cladding

Flue Gas Treatment System

Leachate Treatment System

Incineration Grate

EB is a global leader in advanced combustion systems, offering a complete suite of grate technologies designed for efficient and reliable waste-to-energy conversion. This comprehensive capability positions EB as the industry’s most versatile and technologically advanced provider of grate solutions for modern incineration plants.

EB is the only company worldwide that offers all three of the following technologies in-house:

Forward pushing + tumbling grates

Reverse-acting grates

Water-cooled grates

-

EB GRATE I - Forward Pushing + Tumbling

This innovative grate combines forward-pushing motion with a tumbling effect to ensure uniform waste agitation and optimized combustion. The dynamic movement enhances thermal efficiency and minimizes unburned residues.

Ø Suitable for waste with calorific value rang from 1000-2500kcal/kg.

Ø Suitable for waste, which featured with high moisture, high ash content.

Ø Customized Design from 50 TPD/Line to 1000 EB Grate TPD/Line, all equipped with EU CE Certificates.

Ø Annual Operation Hours≥ 8300 hours.

Ø Lower Slag Loss on Ignition (≤2%), Better Flue Gas emission indicators.

-

EB GRATE II - Reverse-Acting

Engineered for stability and control, the reverse-acting grate operates in a backward motion, promoting consistent burn rates and reduced clinker formation. This design is well-suited for mixed or moist waste streams.

Ø Suitable for waste with medium and high calorific value rang from 2000-3000kcal/kg.

Ø with easy operation method.

Ø Annual Operation Hours≥ 8200 hours.

Ø Customized Design from 300 TPD/Line to 1000 TPD/Line.

-

EB GRATE III - Water-Cooled

Designed for high-temperature durability, this grate features an integrated water-cooling system that maintains structural integrity under extreme heat. Ideal for high-calorific-value or industrial waste.

Ø Suitable for waste with higher calorific value, rang from 2500-5500kcal/kg.

Ø Water cooling, special design, low failure rate.

Ø Customized Design from 300 TPD/Line to 1000 TPD/Line.

Ø Annual Operation Hours≥ 8300 hours.

Ø Can treat industry waste, MSW,RDF, etc.

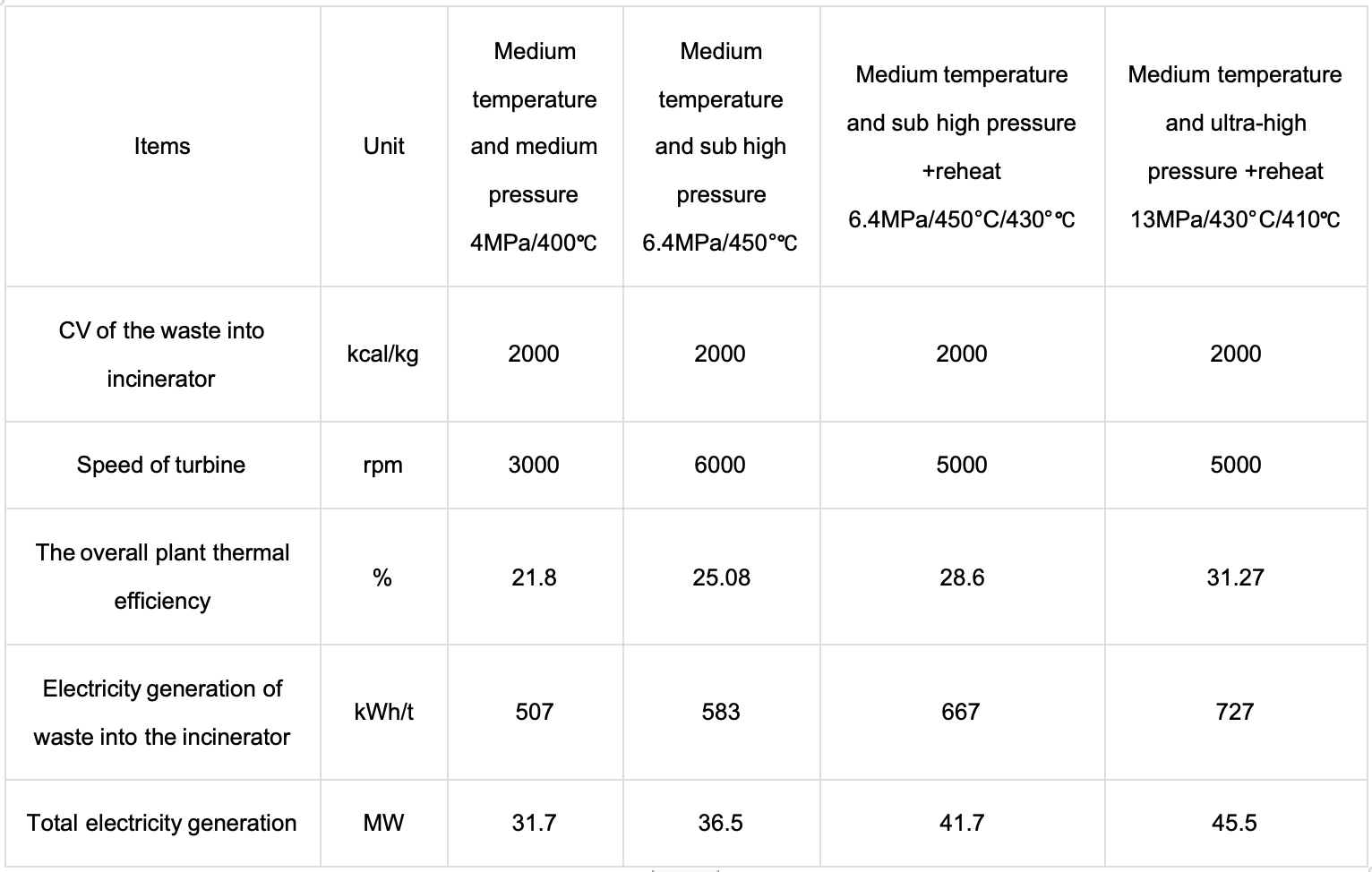

Energy Saving Technology - High Parameter

Ø Medium temperature and sub high pressure Intermediate reheat: 6.4MPa/450℃/430℃,Jiangyin WTE project with capacity 2×500t/d,the overall plant thermal efficiency reaches 28.4%,electricity generation is 595kwh/t.

Ø Medium temperature and ultra-high pressure Intermediate reheat: 13MPa/430℃/410℃,Suzhou WTE project with capacity 6x750t/d,the overall plant thermal efficiency is 30%,electricity generation is 697kwh/t.

Ø At present, high parameter technology have been successfully applied in over 50 WTE projects.

2x500t/d electricity generation comparison with different parameters

GREEN NOVA ENERGY

“ Waste to Energy, Brighten the Future "

Cladding System

Our advanced cladding system not only shields the underlying components from harsh environmental conditions and chemical exposure but also helps enhance structural integrity and safety by containing heat or preventing external damage.

Ø The pioneered and internationally leading tube automation overlay welding production line.

Ø Using 625 welding wire, adopting United States Feimat Special MIG Gas Shielded Welding Power Supply implement overlay welding.

Fly ash will be collected and solidified before being transported to a designated landfill for safe disposal.

Bottom ash will be collected for metal recovery. After the extraction of valuable metals, the remaining material can be processed and used to manufacture construction bricks.

Flue Gas Treatment

Our multi-stage purification process achieves ultra-low emissions and high-efficiency pollutant removal:

• SO₂ removal rate: ≥95%

• HCl removal rate: >99%

• Dioxin emissions: as low as 0.004ng TEQ/Nm³

• Post-treatment performance surpasses EU 2010 directives

Technology highlights:

SNCR + Semi-Dry + Activated Carbon Injection + Bag Filter + SCR + Wet Scrubber + Mist Removal Efficient, compact, and low-maintenance design.

Leachate Treatment System

Balance Tank+Pretreatment+IOC High-efficiency Anaerobic Reactor+A/O(Denitrification and Nitrification ) + Ultrafiltration + Nano / Micro filtration+RO+DTRO+ Immersed Evaporation.

Full recycling and Zero discharge.

Biogas can be directly used for power generation, or transported to natural gas pipeline after purification or to grate furnace for incineration.

No secondary pollution after all the by-product pollutants being properly treated through incineration.

Less space, easy control.